There are many types of rotary kiln equipment produced by Anshan Metal, which can have different effects depending on the materials processed.There are four types of rotary kiln equipment:

1. According to the feeding method: according to the degree of water brought by the material, the rotary kiln equipment can be divided into dry rotary kiln and wet rotary kiln.Wet kilns can be divided into inflow method and spray method.

2. According to the aspect ratio: Rotary kiln equipment can be divided into short kilns and long kilns according to the aspect ratio. Usually the dry short kiln tail is L/D16, and the wet long kiln is L/D=30-42.

3. According to the kiln type: Rotary kiln equipment can be divided into cold-end expansion kilns, straight-end expansion kilns, firing expansion kilns, and expansion kilns at both ends according to the kiln type of the cylinder.

4. According to the heating method: If the rotary kiln equipment is divided according to the heating method, it can be divided into internal heating kilns and external heating kilns. It is usually heated between external heating kilns and can handle high-purity materials.

Our rotary kiln equipment calcination system equipment has passed technological innovation. In this system, the most advanced hydraulic retaining wheel device at home and abroad, a metering plunger pump with high metering accuracy, a high-precision speed regulating valve and a contact graphite block sealing device are used. Domestic advanced technologies.In order to improve the degree of automation, the kiln head adopts industrial TV to watch the fire, the process flow simulates a fluorescent screen, and the calcination belt adopts an infrared scanner to directly reflect the calcination situation of the calcination belt on the computer. The use of these new technologies is intuitive, easy to operate, and reliable.The thermal system has been stabilized and the operating rate of the equipment has been improved. Compared with the equipment of the same specification, the operating rate has been increased by 10%, the output has been increased by 5%-10%, and the heat consumption has been reduced by 15%.

Classification of rotary kiln equipment:

Rotary kiln equipment refers to rotary calcination kilns (commonly known as rotary kilns), which belong to the category of building materials equipment.Rotary kiln equipment can be divided into cement kilns, metallurgical chemical kilns and lime kilns according to the different materials processed.Rotary kiln equipment can be divided into cement kilns, metallurgical chemical kilns and lime kilns according to the different materials processed.Cement kilns are mainly used for calcining cement clinker, which are divided into two categories: dry production of cement kilns and wet production of cement kilns.Metallurgical and chemical kilns are mainly used for magnetization roasting of poor iron ore in iron and steel plants in the metallurgical industry; oxidation roasting of chromium and nickel iron ore; roasting of high alumina vanadium ore in refractory plants and roasting clinker and aluminum hydroxide in aluminum plants; roasting of chromium ore sand and chromium ore powder in chemical plants and other minerals.Lime kilns (that is, active lime kilns) are used for roasting active lime and light burning dolomite used in steel mills and ferroalloy mills.

The structural components of the rotary kiln equipment are composed of:

1.Kiln body: The kiln body of a zinc oxide rotary kiln is generally welded (or riveted) into a cylinder by a 20 mm thick steel plate.

2.Rolling ring: The rolling ring is not directly set on the kiln body, but is installed on the kiln body through the base plate. Its role is to strengthen the zinc oxide rotary kiln body, and at the same time, the weight of the cylinder body can be passed to the support wheel. The zinc oxide rotary kiln used in the production of refractory materials generally has 5 to 8 rolling rings.

3.Support wheel and support wheel axle: The support wheel is mounted on the support wheel axle by hot-loading method, while the support wheel axle is mounted in two bearings with bronze bearings. The water temperature that comes out after the bearing is cooled vertically and horizontally with water should not exceed 25 degrees.

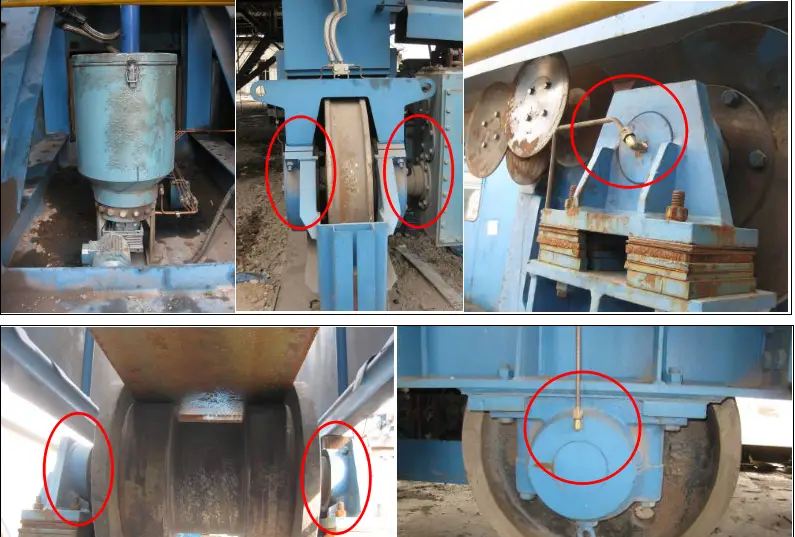

4.Retaining wheel: The retaining wheel is a limiting device that restricts the position of the zinc oxide rotary kiln body on the support wheel, but it cannot stop the movement of the kiln body up and down.

5.Transmission device: Zinc oxide rotary kilns generally use gears to drive the rotation.

Structural characteristics of rotary kiln equipment:

1.Rotary kiln equipment is usually rolled with 20g and Q235-B steel plates that guarantee five mechanical properties, and automatic welding is usually used.The wall thickness of the cylinder body: generally 25mm, the firing belt is 32mm, and the lower part of the wheel belt is 65mm. There is a 38mm thick transition section from the lower part of the wheel belt to the span, so that the design of the cylinder body is more reasonable, not only to ensure the rigidity of the cross-section, but also to improve the force state of the support device.There is a kiln mouth guard plate with high temperature resistance and wear resistance at the discharge end of the cylinder, and the tail end of the cylinder kiln is made of one meter long 1Cr18Ni9Ti steel plate.Among them, the kiln head guard plate and the cold air sleeve form a compartment of the sleeve space, and the cold air is blown from the horn mouth to the cylinder to cool the non-working surface of the kiln head guard plate to facilitate the long-term safe work of this part. Three rectangular solid wheel belts are set on the cylinder body.The gap between the wheel belt and the cylinder backing plate is determined by the amount of thermal expansion. When the kiln is in normal operation, the wheel belt can be moderately set on the cylinder to reduce the radial deformation of the cylinder.

2.The transmission system of rotary kiln equipment uses a single drive, which is driven by a variable frequency motor with a three-stage cylindrical gear reducer with a hard tooth surface, and then drives the open gear pair of the kiln. The transmission device adopts a rubber block coupling to increase the stability of the transmission. It is equipped with an auxiliary transmission device connected to the main power supply, which can ensure that the kiln can still be operated when the main power supply is interrupted, preventing the cylinder from bending and facilitating maintenance.

3.The kiln head sealing of rotary kiln equipment adopts a double-layer flexible sealing device with shell air seal, labyrinth and spring rigid sheet.An appropriate amount of cold air is blown into the horn mouth to cool the guard plate, and the cold air is discharged from the top after being heated; the cold air sleeve body is pressed by the flexible sealing plate under the overlapping heat-resistant spring steel sheet to ensure that the kiln head cylinder body can still maintain a sealing effect when it is slightly biased.

4.The tail seal of the rotary kiln equipment adopts a flexible seal of steel sheet and graphite.The device is simple and convenient to install, safe and reliable to use.

Coking equipment - coal loading trucks, coke pushing trucks, coke stopping trucks, coke quenching trucks

Coking equipment - coal loading trucks, coke pushing trucks, coke stopping trucks, coke quenching trucks