Coking equipment refers to the equipment used to produce coke, which is an important equipment in the iron and steel, foundry, chemical industry and other industries. Its main role is to decompose coal and other substances at high temperature, so as to get coke, gas, tar and other by-products. In modern industrial production, coking equipment has an important position and role.

The whole coking process involves four major vehicles, namely, coal loading truck, coke pushing truck, coke stopping truck and coke quenching truck, and we will talk about the lubrication of the bearings of each part of the four major vehicles.

1, coal loading truck is a hydraulic drive coal loading unit integrating loading, transferring and self-propelled. The main working condition characteristics of coal loading truck: heavy load, high dust, frequent starting and stopping.

2, coke pushing car is mainly used for opening and closing the furnace door of machine side, pushing coke and flat coal, loading coal (cake). Characteristics of working conditions: indirect work, heavy load, shock load, in the coal dust and high temperature environment.

3, Coke stopping car is one of the main equipments of coking equipment, which is used for opening and closing the door of coke oven, guiding the hot coke pushed out by coke pushing car from the charcoal chamber to the coke quenching car, and is responsible for transporting the door and door frame which need to be repaired. The main working condition is characterized by high temperature, heavy load, coal dust and other environments.

4, the main role of coke quenching truck is to transport the high temperature coke falling into the coke grill of the coke stopping truck to the coke quenching tower for water quenching, and the main working condition characteristics: high temperature, heavy load, humidity, water vapor, dusty and other poor working environment, which is even worse than that of the above three trucks.

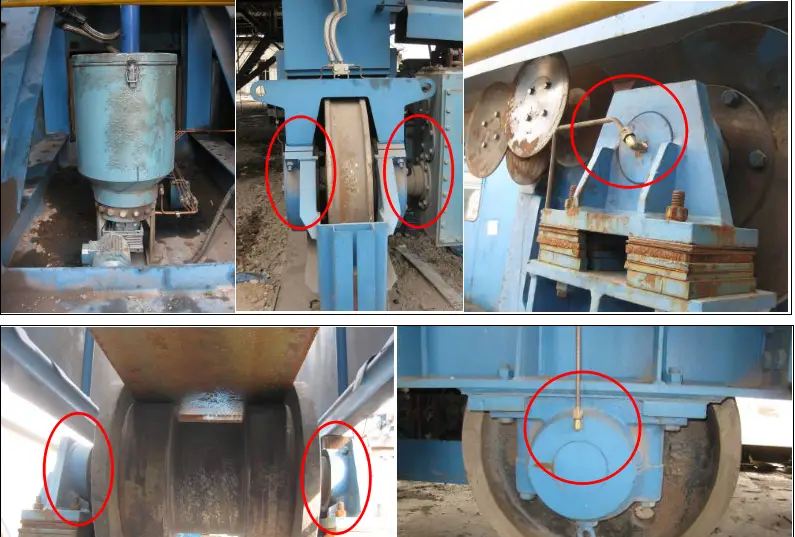

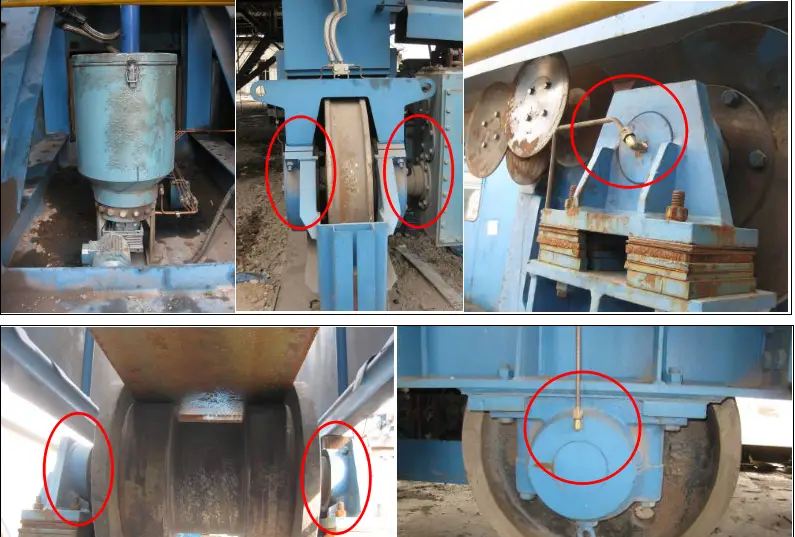

The walking wheels of the four big vehicles as the moving device of the vehicle body, wheel bearings have to bear the load of the whole vehicle and the load, respectively, in the working environment of high temperature, heavy load, low speed, high dust, water vapor, shock load, etc., which requires the lubricating grease to have good sealing performance, good bearing capacity, good anti-wear, extreme pressure performance, oxidation resistance, rust resistance, etc. According to the on-site research and discussion of the U-Run team, for the characteristics of the work of the equipment, the recommended grease is used for the coking branch plant. According to the on-site research and discussion of U-Run team, for the characteristics of coking plant, U-Run high-temperature grease is recommended to be used, which is suitable for high-temperature and heavy-duty working conditions. In view of the fact that the bearings of coal loading trucks, coke pushing trucks, coke stopping trucks (except for coke quenching trucks) are centralized lubrication and grease supply, other bearing parts can be centralized (or manually greased) lubricated with this grease (e.g., bearings of coke pushing rod rollers, bearings of electric motors, and bearings of other transmissions, etc.).