50Mn steel is a high-quality carbon structural steel. The strength, elasticity and hardness of 50Mn steel are high, which are mostly used after quenching and tempering, and the welding performance is poor. 50Mn round steel is used to manufacture heat-treated parts with high wear resistance and high load, such as gears, gear shafts and mandrels with sections below 80 mm. The properties are similar to those of 50# steel, but its hardenability is higher, and the strength, hardness and elasticity after heat treatment are slightly higher than those of 50 # steel. It has poor weldability, overheating sensitivity and temper brittleness tendency. They are used as stress-bearing parts, high wear-resistant parts, and high-stress parts, such as mandrels with a diameter of less than 80 mm. After high-frequency quenching, it can also manufacture train shafts, worms, connecting rods and automobile crankshafts, such as gears, gear shafts, friction discs, mandrels, and flat springs.

| Name | Standard | |||||

| Standard or Agreement | Representative Brand | ASME/

ASTM |

JIS | DIN | EN | |

| High-quality carbon | GB/T | 20 | 1020 | S20C | C22E | C22E |

| 45 | 1045 | S45C | C45E | C45E | ||

| 20Mn | 1022 | SWRCH22K | CK22 | 20M5 | ||

| 50Mn | 1053 | SWRCH50K | CK50 | C45 | ||

| Grade | Chemical Composition% | |||||

| C | Si | Mn | Cr | Ni | Cu | |

| Not greater than | ||||||

| 20# | 0.17-0.24% | 0.17-0.37 | 0.35-0.65 | 0.25 | 0.3 | 0.25 |

| 45# | 0.42-0.50 | 0.17-0.37 | 0.50-0.80 | 0.25 | 0.3 | 0.25 |

| 20Mn | 0.17-0.24 | 0.17-0.37 | 0.70-1.00 | 0.25 | 0.25 | 0.25 |

| 50Mn | 0.48-0.56 | 0.17-0.37 | 0.70-1.00 | 0.25 | 0.25 | 0.25 |

| Grade | Mechanical Property | Hardness of delivery

Not greater than |

|||||

| Tensile Strength

σb (MPa) |

Yield Strength

σs (MPa) |

Elongation Rate

δ5 (%) |

Shrinkage Ratio/ψ(%) | Impact Energy/Akv (J) | |||

| Not less than | Non thermal treatment/(HB) | Annealed steel/(HB) | |||||

| 20# | 410 | 245 | 25 | 55 | 156 | ||

| 45# | 600 | 355 | 16 | 40 | 39 | 229 | 197 |

| 20Mn | 450 | 275 | 24 | 50 | 197 | ||

| 50Mn | 645 | 390 | 13 | 40 | 31 | 255 | 217 |

The heat treatment process of 50Mn steel is a commonly used heat treatment method for steel processing. This process mainly involves heating and cooling steel to change its microstructure and properties, thereby improving its strength, hardness, and wear resistance. In this article, we will provide a detailed introduction to the steps, influencing factors, and application areas of the heat treatment process for 50Mn steel.

Heating

Firstly, before conducting heat treatment on 50Mn steel, it is necessary to heat it to an appropriate temperature. The heating temperature is usually determined based on the composition, morphology, and required properties of the steel. During the heating process of 50Mn steel, attention should be paid to avoiding temperatures that are too high or too low to avoid irreversible damage to the steel.

Holding time

Once the appropriate heating temperature is reached, it is necessary to maintain it for a certain period to ensure that the entire steel is uniformly heated. The holding time depends on the size and thickness of the steel. Steel of larger size and thickness requires longer holding time to ensure that its internal temperature reaches equilibrium.

Cooling

After completing the heating and holding time, the steel needs to be rapidly cooled. The cooling rate has a significant impact on the performance of steel. Common cooling methods include water quenching, oil quenching, and air cooling. The choice of appropriate cooling method depends on the required steel properties.

Various factors influence the effect of the heat treatment process on 50Mn steel.

Temperature

Heating temperature is one of the key factors affecting the effectiveness of heat treatment. Excessive or insufficient temperature can lead to unsatisfactory results. When determining the heating temperature, it is necessary to consider the composition, morphology, and required properties of the steel and refer to relevant standards or empirical data.

Holding time

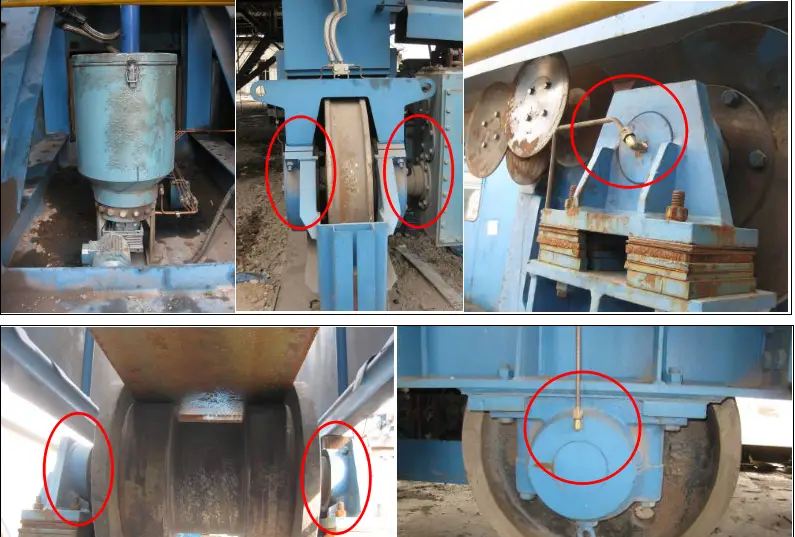

<p style="margin-right: auto; margin-bottom: 12px; margin-left: auto; border: 0px; color: #222222; font-f Coking equipment - coal loading trucks, coke pushing trucks, coke stopping trucks, coke quenching trucks

Coking equipment - coal loading trucks, coke pushing trucks, coke stopping trucks, coke quenching trucks