45# steel is a carbon structural steel with a carbon content of 0.45%. It is characterized by low price, good cutting performance, high hardness after quenching, and good toughness and wear resistance after quenching and tempering. 45# steel is widely used in the manufacture of structural parts and low-end plastic molds.

“45# steel” is a popular name, and the symbol is generally recorded as “45#”. In fact, the GB standard steel number is “45#”, it is not a serial number, and it is not very accurate to pronounce “45# steel”.

Similar grades of 45# steel are S45C (JIS) and 1045 (AISI). In addition, there is SM45 grade in my country’s metallurgical technology standards that specifically indicates the use of plastic molds. Compared with 45# steel, SM45 has lower phosphorus and sulfur content and better steel purity.

| Standard | GB/T 699 | Grade | 45 |

| C | 0.42-0.50 | Cr | ≤0.25 |

| Si | 0.17-0.37 | Ni | ≤0.30 |

| Mn | 0.50-0.80 | Cu | ≤0.25 |

| Classified by phosphorus and sulfur | P | S | |

| (45) | ≤0.035 | ≤0.035 | |

| High quality steel (45A) | ≤0.030 | ≤0.030 | |

| Super high quality steel (45E) | ≤0.025 | ≤0.020 | |

| Standard | YB/T 094 | AISI | JIS G4051 |

| Grade | SM45 | 1045 | S45C |

| C | 0.42-0.48 | 0.43-0.50 | 0.42-0.48 |

| Si | 0.17-0.37 | — | 0.15-0.35 |

| Mn | 0.50-0.80 | 0.60-0.90 | 0.60-0.90 |

| P | ≤0.030 | ≤0.030 | ≤0.030 |

| S | ≤0.030 | ≤0.050 | ≤0.035 |

| Sample blank size (mm) | 25 | |

| Recommended heat treatment (℃) | Normalizing | 850 |

| Hardening | 840 | |

| Tempering | 600 | |

| Mechanical properties | Tensile strength Mpa | ≥600 |

| Yield strength Mpa | ≥355 | |

| Elongation % | ≥16 | |

| Reduction of area % | ≥40 | |

| Impact energy J | ≥39 | |

| Delivery hardness HBS | Unheated steel | ≤229 |

| Annealed steel | ≤197 | |

Note: For steels larger than 80mm, the elongation and reduction of area after fracture are allowed to be reduced by 2% and 5% respectively compared with the above table.

Recommended quenching process specification: quenching temperature is 820~860℃, water cooling or oil cooling, hardness ≥50HRC.

Recommended tempering process specification: tempering temperature is 500~560℃, air cooling, hardness is 25~33HRC.

Tempering in this temperature range is quenched and tempered. Quenching and tempering makes 45# steel have a good balance of strength, plasticity and toughness, with good overall performance, and can adapt to the alternating load environment.

The surface hardness of 45# steel is low after quenching and tempering, and it is not wear-resistant. Therefore, quenching and tempering + surface quenching are used to improve the surface hardness of parts.

The relationship between tempering temperature and hardness is shown in the following table:

| Tempering temperature | After quenching | Unit (℃) | |||||

| 200 | 300 | 400 | 500 | 550 | 600 | ||

| Hardness HRC | 57 | 55 | 50 | 41 | 33 | 26 | 22 |

Note:

|

|

| Figure.1 (100×) | Figure.1 (500×) |

The normalizing of 45# steel is to heat the steel to 30~50℃ above Ac3, and cool it naturally in the air after heat preservation. The main difference between it and complete annealing is that the cooling rate is faster, and the purpose is to normalize the structure of the steel and make the pearl shine The volume increases and becomes thinner, reducing the amount of ferrite.

If 45# steel is used for ordinary structural parts, normalizing can be used as the final heat treatment. Normalizing can improve the structure after casting or forging, refine the austenite grains, homogenize the structure, and form a fine and uniform ferrite and pearlite structure. The grain size can reach 8 levels, as shown in Figure 1. It can be seen that the layer spacing of pearlite has reached a very fine degree, thereby improving the strength, hardness and toughness of the steel.

45# steel is also the most commonly used quenched and tempered steel. It must be normalized before quenching and high temperature tempering to obtain a uniform and fine structure as an important process of pre-heat treatment.

|

|

Previous :

A Comprehensive Guide to 50Mn steel

Next :

Why do steel mills build supporting lime kilns?

Related News

Read More >>

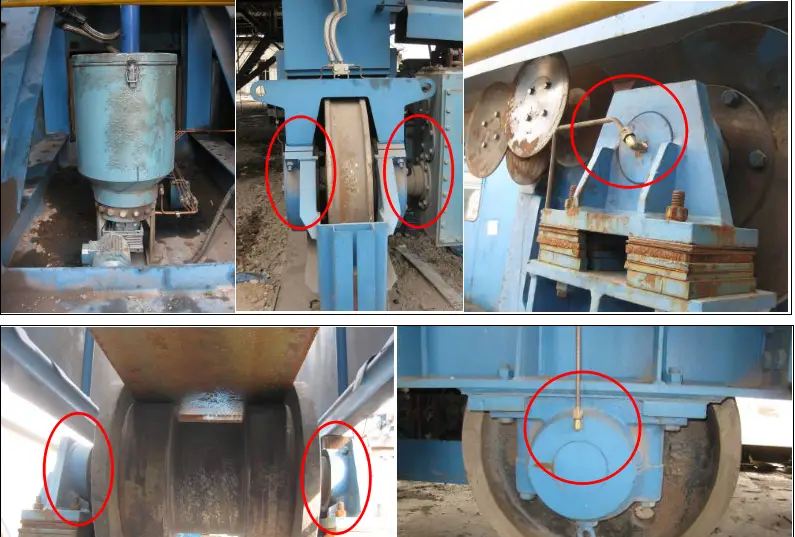

Coking equipment - coal loading trucks, coke pushing trucks, coke stopping trucks, coke quenching trucks

Coking equipment - coal loading trucks, coke pushing trucks, coke stopping trucks, coke quenching trucks

Apr .03.2024

Coking equipment - coal loading trucks, coke pushing trucks, coke stopping trucks, coke quenching trucks

|